Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

In critical industries such as healthcare, manufacturing, aerospace, and water treatment, a stable and reliable supply of high-pressure oxygen is essential. The Oil-Free Oxygen Booster, as a breakthrough technology, is becoming the preferred solution for high-pressure oxygen applications thanks to its outstanding safety, purity, and energy efficiency.

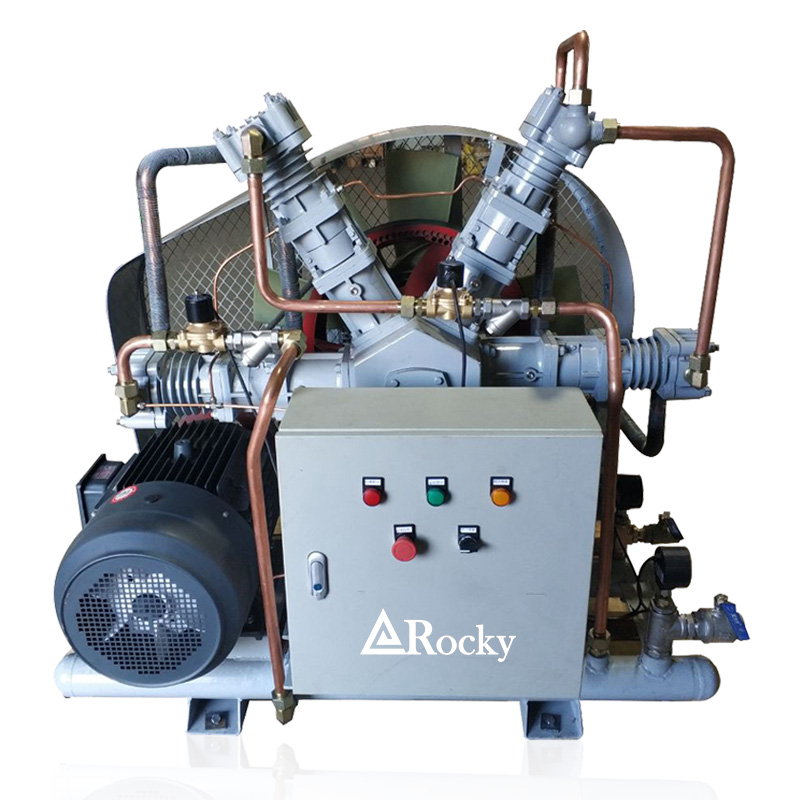

An Oil-Free Oxygen Booster is a special compressor designed specifically to increase oxygen pressure. Its core feature is that the entire compression process operates completely without lubricating oil, thereby entirely eliminating the risk of oil contaminating the oxygen stream. The equipment is typically constructed from oxygen-compatible materials and integrates multiple safety and control features to ensure safe interaction with highly reactive oxygen.

Absolute Purity, Zero Contamination Risk

Even with advanced filtration, traditional oil-lubricated compressors carry a minor risk of oil molecules entering the gas stream. Oil-free design eliminates this possibility at its root, guaranteeing 100% pure oxygen output. This is decisive for fields with zero tolerance for contamination, such as breathing gases, precision welding, and semiconductor manufacturing.

Inherent Safety, Eliminating Fire Hazards

Oxygen is a strong oxidizer. Contact with oil can easily cause intense combustion or even explosion. Oil-free technology removes this fundamental ignition source, minimizing system fire risk and providing an inherently safer operating environment.

Low Maintenance, High Reliability

The oil-free design eliminates complex oil circuits, oil filters, and the need for regular oil changes. This not only reduces long-term operating costs and maintenance downtime but also simplifies system architecture, enhancing overall equipment reliability.

Energy Efficient

Advanced piston or diaphragm design, combined with high-efficiency drive systems, significantly improves the energy efficiency ratio of modern oil-free boosters. Precise pressure control and variable frequency drives (if equipped) can further match actual demand, avoiding energy waste.

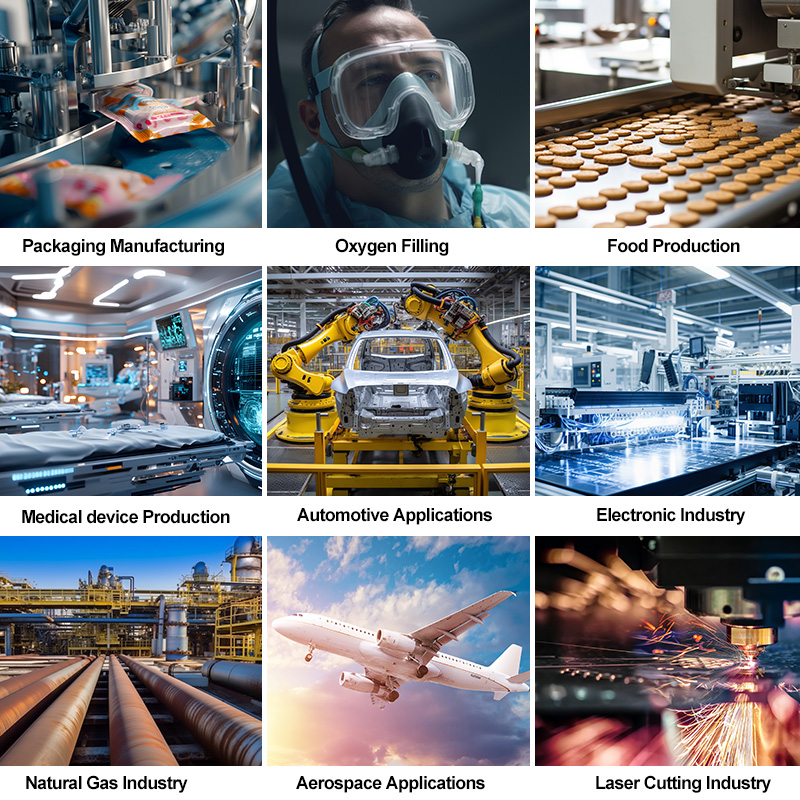

Healthcare: Provides a reliable high-pressure source for hospital central oxygen systems, dental clinics, and home oxygen therapy devices.

Industrial Manufacturing: Used in metal cutting, welding (especially high-precision welding), glass manufacturing, and flame spraying processes.

Aerospace: Supplies pressurized oxygen for aircraft and spacecraft life support systems and ground testing equipment.

Water Treatment: Used in ozone generation systems to provide a high-pressure oxygen source for efficient disinfection.

Laboratories & Research: Meets the needs of various experimental and analytical equipment requiring high-pressure, pure oxygen.

Energy & Chemical: Plays a key role in processes like coal gasification and fuel cell testing.

When choosing the right equipment, focus on the following:

Material Compatibility: All components in contact with oxygen must use "oxygen-compatible" materials (e.g., specific stainless steels, bronze, PTFE) to prevent material degradation or combustion in high-pressure, oxygen-rich environments.

Maximum Output Pressure & Flow Rate: Clearly define the pressure and continuous flow required for your process, ensuring the equipment capacity has an appropriate margin.

Cooling Method: Choose between air-cooling (suited for small/medium units) or water-cooling (suited for large, continuous-duty units) based on power and operational cycles.

Control & Monitoring: Advanced control panels, pressure regulation, safety relief valves, and fault alarm systems are essential for safe and efficient operation.

Certifications & Standards: Ensure the equipment complies with relevant international or industry safety standards, such as ISO, ASME, or specific medical device certifications.

As a professional compressed air solutions provider, we deeply understand the special requirements and safety standards for oxygen handling. Our series of Oil-Free Oxygen Booster products integrate the following core values:

Designed for Oxygen: From material selection to sealing technology, every detail adheres to the highest grade oxygen safety specifications.

Exceptional Performance: Offers a wide range of pressures and flow rates to meet diverse needs from laboratories to large-scale industries.

Intelligent Control: Features user-friendly control systems for precise pressure regulation, operational status monitoring, and early warning functions.

Full Lifecycle Support: We provide comprehensive service support, from selection consultation and professional installation to maintenance and technical training.

Whether you are upgrading an existing system or designing a new process flow, choosing the right Oil-Free Oxygen Booster is a critical step in ensuring safety, efficiency, and product quality.

Contact our team of technical experts today for a free consultation and a customized solution. Let us help you find the perfect oxygen boosting equipment for your application needs, providing a solid foundation for your critical operations.