Views: 0 Author: Site Editor Publish Time: 2025-09-01 Origin: Site

When air is compressed, it produces a byproduct called oily condensate—a mix of water and compressor lubricant. This waste can't be drained directly into public systems because it contains far more oil than environmental regulations allow. Left untreated, it risks heavy fines, equipment damage, and environmental harm.

That's where an oil-water separator comes in.

The EPA requires that water discharged into public systems contain fewer than 40 PPM of oil. In reality, condensate from a compressed air system often has 300 PPM or more—over seven times the limit. Without treatment, disposal is both risky and expensive.

Using an oil-water separator helps you:

Ø Stay compliant with environmental rules

Ø Reduce waste hauling and disposal costs

Ø Protect your equipment from oil buildup

Ø Simplify maintenance across your system

Facilities typically manage oily condensate in one of two ways:

1. Collection & hauling – Storing waste in drums for off site disposal. Effective but costly and labor intensive.

2. On-site treatment – Filtering condensate with an oil-water separator before discharge. Cleaner, compliant, and much more economical long term.

A separator connects to drains throughout the system—compressor, dryer, aftercooler, filters, and tanks, collecting all condensate for treatment.

The process typically involves:

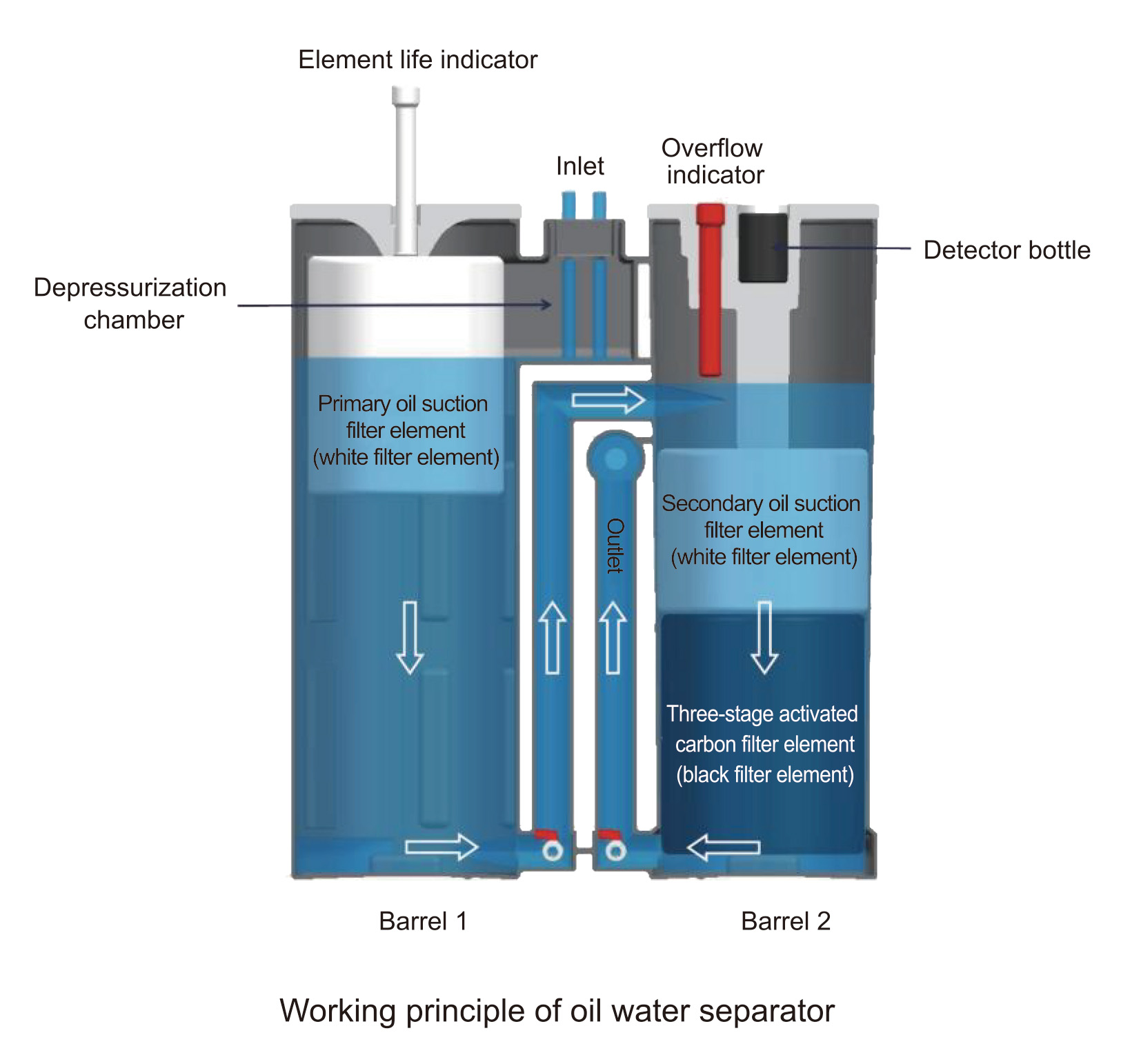

Ø Condensate flows into the depressurization chamber, where pressure-reducing cotton filters out granular impurities and

Ø The condensate enters Barrel 1, where the primary oil-absorbing cartridge absorbs most of the oil.

Ø The remaining oil in the condensate is adsorbed by the secondary oil-absorbing filter element in Barrel 2.

Ø After de-oiling, the condensate is passed through a three-stage activated carbon cartridge to absorb any remaining hydrocarbon compounds.

Ø The clean, de-oiled condensate meets national environmental protection requirements and can be safely discharged through the outlet.

Ø The filter life indicator rod (white) visually displays the filter element's oil absorption capacity. When the rod sinks to the bottom, it indicates that the filter is saturated and needs replacement.

Modern systems combine several separation methods for best results:

1. Gravity separation – Oil rises, water settles.

2. Absorption/adsorption – Filter media attract and hold oil.

3. Coalescing media – Small oil droplets combine and separate faster.

Each method has strengths, and many separators layer them together to meet strict discharge limits.

Sizing a separator correctly is critical—it's usually based on the system's airflow (CFM). Higher airflow generates more condensate, requiring greater filter capacity. Factors like temperature, oil type, and operating hours also affect filter life.

Maintenance is simple but essential:

1. Check water clarity regularly and replace filters if discharge looks cloudy.

2. Inspect tanks periodically for sludge or buildup.

3. Change cartridges annually (or more often in higher demand systems).

A basic service schedule keeps you compliant and avoids costly downtime.

The ROWS Series Oil-Water Separators effectively remove condensate from mineral oils, semi-synthetic oils, fully synthetic

oils, and their emulsions, ensuring the discharged condensate meets national environmental protection standards.

An oil-water separator isn't just an environmental requirement, it's a smart investment! It lowers operating costs, simplifies waste management, and helps protect your compressed air system.

If you're not sure which separator fits your setup, talk with a compressed air specialist at Rocky. The right system pays for itself in reduced waste hauling, easier maintenance, and peace of mind knowing you're always compliant.